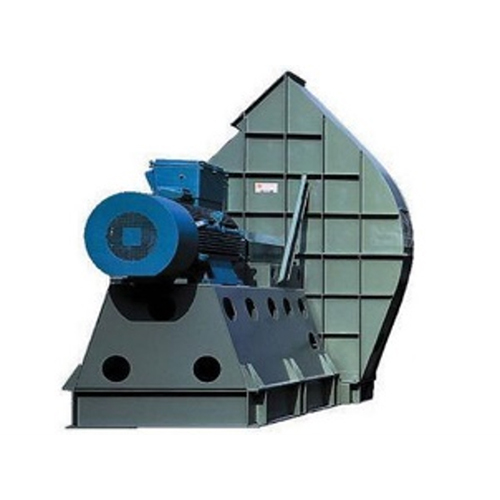

FUEL FEEDING SYSTEM

Product Details:

- Usage Industrial

- Size Standard

- Condition New

- Color Grey

- Product Type FUEL FEEDING SYSTEM

- Voltage 220-440 Volt (v)

- Material Stainless Steel

- Click to View more

FUEL FEEDING SYSTEM Price And Quantity

- 1 Number

FUEL FEEDING SYSTEM Product Specifications

- New

- Grey

- Standard

- Industrial

- Stainless Steel

- 220-440 Volt (v)

- FUEL FEEDING SYSTEM

FUEL FEEDING SYSTEM Trade Information

- 5 Number Per Month

- 7 Days

Product Description

A fuel feeding system plays a crucial role in delivering solid, liquid, or gaseous fuels to the boiler furnace in a controlled and reliable manner, ensuring efficient combustion and optimum boiler performance.

With strong engineering capabilities and proven field experience, we provide customized solutions and retrofits to upgrade existing fuel feeding systems, improve efficiency, reduce breakdowns, and adapt boilers to alternative fuels.

Our Expertise

-

New Fuel Feeding Systems

-

Chain grate, screw feeder, pneumatic and hydraulic fuel feeders.

-

Vibratory and mechanical conveying systems.

-

Automatic and manual fuel handling arrangements.

-

-

Modification & Upgradation

-

Conversion of boilers from coal to biomass/alternative fuels.

-

Optimization of existing feeding systems for higher efficiency.

-

Replacement of worn-out feeders, hoppers, and conveyors.

-

Retrofitting of feeding mechanisms to suit AFBC / CFBC boilers.

-

-

IBR & Statutory Compliance “ Liaisoning for inspection, approval, and certification (where applicable).

Key Features

-

Efficient Fuel Delivery “ Uniform and controlled fuel feeding to the boiler furnace.

-

Durable Construction “ Heavy-duty feeders, hoppers, and conveyors built for continuous operation.

-

Fuel Flexibility “ Compatible with coal, lignite, biomass, bagasse, husk, and other fuels.

-

Energy Efficient “ Reduced fuel wastage and better combustion efficiency.

-

Custom-Engineered “ Designed to match boiler capacity, type, and plant requirements.

-

Easy Maintenance “ Simple design with wear-resistant components for longer life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+