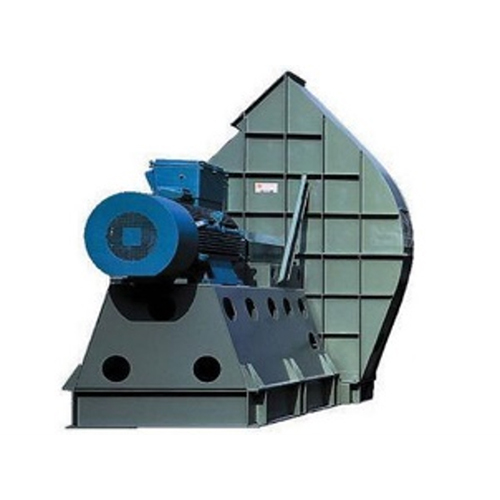

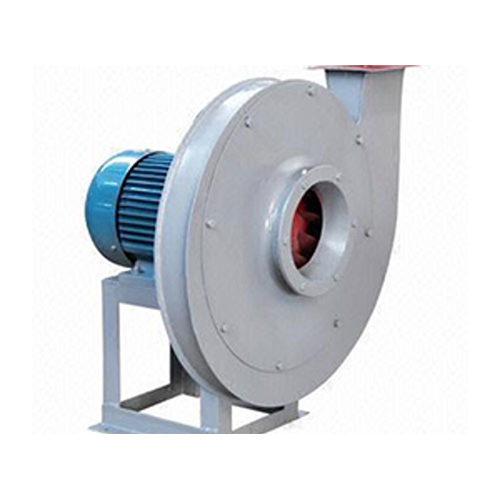

SPARK ARRESTOR

Product Details:

- Color Silver

- Size Standard

- Voltage 220-440 Volt (v)

- Condition New

- Product Type SPARK ARRESTOR

- Usage Industrial

- Material Stainless Steel

- Click to View more

SPARK ARRESTOR Price And Quantity

- 1 Unit

SPARK ARRESTOR Product Specifications

- 220-440 Volt (v)

- New

- SPARK ARRESTOR

- Silver

- Stainless Steel

- Standard

- Industrial

SPARK ARRESTOR Trade Information

- 5 Unit Per Month

- 7 Days

Product Description

We are leading manufacturers of Spark Arrestors, designed to prevent the emission of sparks and burning particles from industrial boilers, furnaces, chimneys, and exhaust systems. A spark arrestor is a critical safety device that protects downstream equipment, prevents fire hazards, and ensures compliance with environmental and safety regulations.

Our spark arrestors are engineered with robust construction, high filtration efficiency, and low-pressure drop, making them reliable and effective across multiple industries.

Working Principle

The Spark Arrestor works by capturing and quenching sparks from flue gases using:

-

Deflection Mechanism “ Sparks are diverted and lose energy.

-

Filtration Mesh / Baffles “ Sparks are trapped before reaching the chimney.

-

Cooling Effect “ Sparks lose temperature and extinguish safely.

This ensures only clean gases are discharged, protecting both equipment and the environment.

Key Features

-

High Efficiency “ Effectively eliminates sparks and glowing particles.

-

Heavy-Duty Construction “ Built with MS/SS materials for long life.

-

Low Pressure Drop “ Ensures smooth gas flow without affecting draft.

-

Custom Design “ Available in cylindrical, box-type, and modular designs.

-

Easy Maintenance “ Removable screens and easy-to-clean construction.

-

Compliance Ready “ Meets industry fire-safety and emission norms.

Applications

-

Boiler Chimneys & Stacks

-

Thermal Power Plants

-

Biomass & Waste-to-Energy Plants

-

Steel & Cement Industries

-

Sugar & Paper Mills

-

Diesel Engine Exhaust Systems

Advantages

” Prevents fire hazards caused by sparks in chimney exhausts

” Protects ESP, Bag Filter, and downstream equipment

” Ensures safer working environment

” Complies with pollution control & fire safety regulations

” Long-lasting, durable, and low-maintenance design

Why Choose Us

-

Expertise in design, fabrication, and erection of spark arrestors

-

Proven solutions for industrial boilers and exhaust systems

-

Custom-engineered designs to match capacity and application

-

End-to-end support including installation & commissioning

-

Reliable after-sales service and spare availability

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+