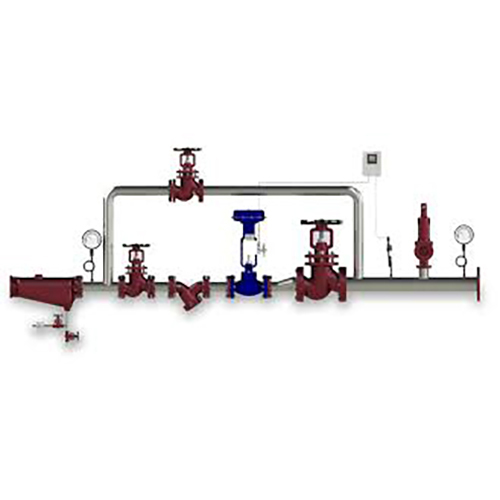

SUPER HEATER

Product Details:

- Usage Industrial

- Product Type SUPER HEATER

- Color Red

- Size Standard

- Condition New

- Material Stainless Steel

- Click to View more

SUPER HEATER Price And Quantity

- 1 Number

SUPER HEATER Product Specifications

- SUPER HEATER

- Industrial

- Red

- Stainless Steel

- Standard

- New

SUPER HEATER Trade Information

- 5 Number Per Month

- 7 Days

Product Description

We are specialists in the bending, fabrication, and erection of Superheater Coils, a vital component of modern boilers that increases the temperature of saturated steam to produce superheated steam for turbines and process applications. Designed to withstand high pressure and extreme temperatures, our superheaters are manufactured and installed with precision to ensure maximum efficiency, reliability, and long service life.

With advanced bending facilities, skilled manpower, and strong expertise in boiler auxiliaries, we deliver end-to-end superheater solutions ” from fabrication and on-site erection to IBR documentation and approvals.

Our Expertise

-

Tube Bending “ Precision cold/hot bending of superheater tubes as per boiler drawings.

-

Fabrication & Assembly “ Manufacturing of radiant, convective, or platen-type superheaters.

-

Erection & Installation “ On-site erection, welding, and alignment with skilled teams.

-

IBR Liaisoning “ Complete documentation, inspection, and statutory approvals under IBR norms.

-

Repair & Retrofitting “ Replacement of damaged coils and revamping of existing superheaters.

-

Custom Designs “ Tailored as per boiler type, capacity, and process requirements.

Key Benefits

-

Higher Efficiency “ Delivers dry superheated steam for better turbine and process performance.

-

Durable Construction “ High-grade alloy steels for resistance against creep, corrosion, and thermal stress.

-

Improved Boiler Life “ Minimizes moisture content and reduces erosion in turbines/piping.

-

Compliance Assured “ Full IBR-approved fabrication and erection services.

-

Reduced Downtime “ Quick turnaround for installation, repair, or replacement.

- Why Choose Us

” Proven expertise in superheater fabrication & erection

” Advanced tube bending and welding technology

” Skilled and certified workforce

” End-to-end solutions including IBR approvals

” Commitment to safety, precision, and timely delivery

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+