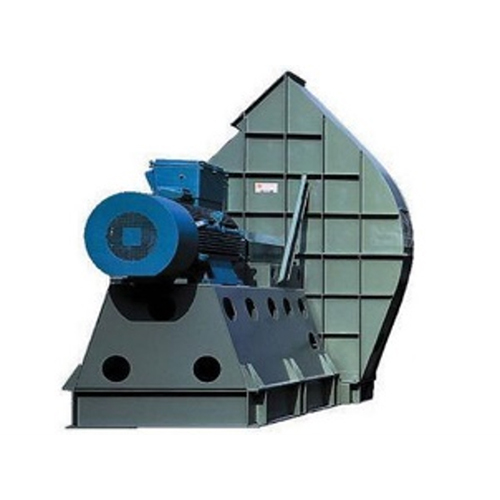

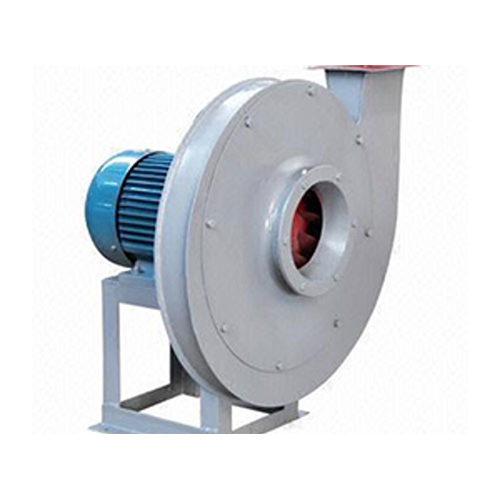

WATER PRE HEATER

Product Details:

- Usage Industrial

- Color Silver

- Voltage 220-440 Volt (v)

- Product Type WATER PRE HEATER

- Size Standard

- Condition New

- Material Stainless Steel

- Click to View more

WATER PRE HEATER Price And Quantity

- 1 Unit

WATER PRE HEATER Product Specifications

- Standard

- New

- Stainless Steel

- Silver

- Industrial

- WATER PRE HEATER

- 220-440 Volt (v)

WATER PRE HEATER Trade Information

- 5 Unit Per Month

- 7 Days

Product Description

A Water Pre-Heater is a vital heat recovery equipment that utilizes waste heat from flue gases or other sources to preheat boiler feedwater. This improves boiler efficiency, reduces fuel consumption, and minimizes thermal stresses on boiler tubes.

Our WPH systems are designed with robust construction, high heat transfer efficiency, and compliance with IBR standards, making them suitable for a wide range of industrial applications.

Our Expertise

-

Design & Engineering of custom-built WPH units based on boiler capacity.

-

Fabrication & Supply of shell-and-tube or finned-tube type water pre-heaters.

-

On-site Erection & Installation with proper alignment and safety measures.

-

Retrofitting & Upgradation of existing systems for better efficiency.

-

IBR Liaisoning for inspection and approval (where applicable).

Key Features

-

Enhanced Boiler Efficiency “ Saves up to 5“10% of fuel by recovering waste heat.

-

Durable Construction “ Designed with MS/SS tubes, finned or bare, for long life.

-

Optimized Heat Transfer “ Efficient design ensuring maximum utilization of flue gas energy.

-

Reduced Thermal Shock “ Gradual heating of feedwater protects boiler tubes.

-

Low Maintenance “ Easy-to-clean design with accessible headers.

-

Customizable Design “ Configurations as per boiler load and flue gas characteristics.

Applications

-

Thermal & Captive Power Plants

-

Industrial Boilers (AFBC / CFBC)

-

Sugar Mills, Paper & Textile Plants

-

Chemical & Fertilizer Industries

-

Cement & Steel Industries

Why Choose Us

” Proven expertise in heat recovery systems for boilers

” Custom designs for energy optimization

” Skilled workforce & advanced fabrication facilities

” IBR-compliant solutions with liaisoning support

” End-to-end project execution “ design to commissioning

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+